KOMATSU PC220LC-12

2025

Komastu

PC220LC-12

New

Ontario

Built to empower operators

The PC220LC-12 is designed to empower operators to achieve high productivity on your jobsite while controlling costs. With a strong focus on enhancing the cab, it was engineered with the goal of creating the most comfortable, advanced, customizable and efficient working environment in a Komatsu excavator.

- The cab is 28% larger with 30% more legroom and 50% improved visibility*

- Large, intuitive and customizable high-definition cab monitor

- New multi-function, comfortable operator seat with heating and air suspension

- Up to a 20% reduction in fuel and diesel exhaust fluid costs*

Note: *All percentage claims are based on a comparison to the previous PC210LC-11 model. Cost reductions are achieved through a new electronically controlled hydraulic system and a high-output engine.

Features and benefits

Updated cab design

This new cab design enhances operator comfort and visibility, helping to maintain productivity during long shifts. Improved legroom and visibility (compared to the PC210LC-11).

Intuitive and customizable cab monitor

A clear interface, combined with high-definition visuals, provides an intuitive, user-friendly, and customizable experience for the operator. Joystick controls are also customizable.

Air-suspension multi-function seat

Komatsu has improved the operator experience and comfort with upgraded seats. The most innovative seat has variable heat/cool settings and is adjustable to a maximum of 60 mm across six levels. The premium seat also features shock absorption providing additional comfort. The air suspension feature can be adjusted to a maximum height of 80 mm, with no level intervals.

User interface enhancements

Upgraded from the previous model to an 8-inch touch-panel monitor. High-resolution display and easy access to various machine functions. Intuitive controls for attachment, working mode, and travel mode.

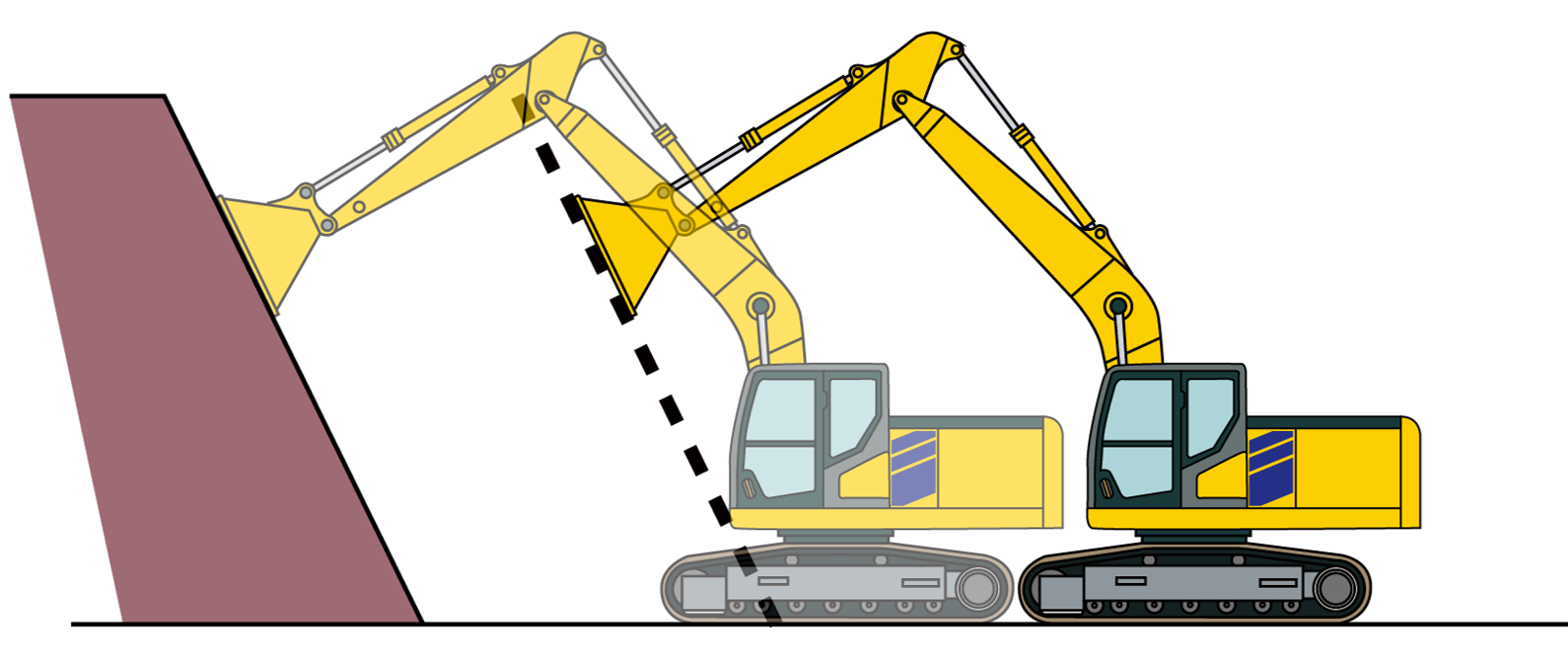

Revamped work equipment

Enhanced work equipment through thick plating and reinforced castings. Provides additional strength and power for the operator in tough work conditions.

Enhanced operator features promote zero harm

Rollover avoidance alerts. KomVision 360 camera for enhanced bird’s eye views. Unbuckled seat belt reminders and human detection alerts. Courtesy lights and handrails designed for high visibility.

2D boundary control

Automatically decelerates operations near set virtual walls. Can be set in various directions. Icon indicators and cab buzzers deliver proximity-to-boundary alerts.

.png)

2D machine control

Enhances excavation and grading by automatically managing the cutting edge's position relative to a design surface. Includes auto stop control, auto grade assist, and touch point functionality

Control maintenance costs

Compared to the PC210LC-11, up to a 20% reduction in overall maintenance costs can be achieved from extended intervals for hydraulic oil and filter replacement, as well as KDPF cleaning.

Engine

| Model | Komatsu SAA4D107E-5 (U.S. EPA Tier 4 Final and EU Stage 5 emissions certified.) |

| Aspiration | Turbocharged, aftercooled |

| Number of cylinders | 4 |

| Bore | 4.21 in |

| Stroke | 4.88 in |

| Piston displacement | 272.17 in³ |

| Horsepower: | |

| SAEJ1995 - Gross (HP) | 173 HP |

| ISO 9249 / SAE J1349 - Net (HP) | 72 HP |

| Rated rpm | 2,000 rpm |

| Fan drive method for radiator cooling | Mechanical |

| Governor | All-speed , electronic |

| *EPA Tier 4 Final emissions certified |

Hydraulics

Type: HydrauMind (Hydraulic Mechanical Intelligence New Design) system, closed-center system with load sensing valves and pressure compensated valves

| Number of selectable working modes | 4 |

| Main pump: | |

| Type | Variable displacement piston type |

| Pumps for | Boom, arm, bucket, swing, and travel circuits |

| Maximum flow | 133.1 US gpm |

| Supply for control circuit | Self-reducing valve |

| Hydraulic motors: | |

| Travel | 2 x axial piston motors with parking brake |

| Swing | 1 x axial piston motor with swing holding brake |

| Relief valve setting: | |

| Implement circuits | 5,400 psi |

| Travel circuit | 5,400 psi |

| Swing circuit | 410 psi |

| Pilot circuit | 470 psi |

| Hydraulic cylinders: | |

| Number of cylinders | Bore x Stroke x Rod Diameter |

| Boom / 2 | 5.1 x 52.7 x 3.5 in |

| Arm / 1 | 5.5 x 58.7 x 3.9in |

| Bucket / 1 | 4.7 x 43.9 x 3.4 in |

Drives and Brakes

| Drive method | Water-cooled, 4-cycle, direct injection |

| Maximum drawbar pull | 45,415 lbs. |

| Gradeability | 70%, 35° |

| Maximum travel speed: (Auto-Shift) | |

| High | 3.4 mph |

| Mid | 2.6 mph |

| Low | 1.9 mph |

| Service brake | Hydraulic lock |

| Parking brake | Mechanical disc brake |

Swing System

| Drive method | Hydrostatic |

| Swing reduction | Planetary gear |

| Swing circle lubrication | Grease-bathed |

| Service brake | Hydraulic lock |

| Holding brake/Swing lock | Mechanical disc brake |

| Swing speed | 12.4 rpm |

Undercarriage

| Center frame | X-frame | |

| Track frame | Box-section | |

| Seal of track | Sealed track | |

| Track adjuster | Hydraulic | |

| Number of shoes | 49 each side | |

| Number of carrier rollers | 2 each side | |

| Number of track rollers | 9 each side |

Coolant & Lubricant Capacity (Refilling)

| Fuel tank | 92.5 US gal |

| Coolant | 7.6 US gal |

| Engine | 4.8 US gal |

| Final drive, each side | 1.1 US gal |

| Swing drive | 1.7 US gal |

| Hydraulic tank | 31.4 US gal |

| Hydraulic system | 61.8 US gal |

| DEF tank | 16.6 US gal |

Operating Weight (Approximate)

| Triple-Grouser Shoes | Operating Weight: | Ground Pressure |

| 28 in | 53,352 lbs. | 6.7 psi |

| 31.5 in | 54,675 lbs. | 5.9 psi |

Sound Performance

| Exterior – ISO 6395 | 100 dB(A) |

| Operator – ISO 6396 | 24800 dB(A) |

- Dial type fuel control

- Auto-decelerator

- Swing lock switch

- Working mode selector

- Three-gear travel

- Travel automatic gear shift

- Auto idle stop

- ROPS cab (compliant with ISO 12117-2)

- Keyless start

- Engine shutdown secondary switch

- Battery disconnect switch

- Cab rear window for emergency escape

- Emergency escape hammer

- Large movable side view mirror (left and right) and side confirmation mirror

- LED working lamp (left and right boom, front right of the cab, rear of machine)

- LED headlamp (two on cab)

- KomVision (Object avoidance)

- Oil pressure lock lever

- Retractable seat belt

- Handrail

- Anti-slip plate

- Thermal guard

- Full cover fan guard

- Firewall divider

- Travel alarm (with on/off switch function)

- Reflector

- Large damper-mounted pressurized cab

- Air suspension seat

- High definition 8 inch touch panel monitor

- Large-capacity, fully automatic air conditioner with fresh air intake

- Defroster

- Room light

- Drink box

- Front window sunroller blind

- Luggage box

- Magazine rack

- USB charging terminal

- Cup holder

- Remote intermittent wiper (with washer)

- Multi functional audio

- Washable floor mat

- Footrest

- Travel pedal with wing

- 12 V accessory power supply

- Openable polycarbonate roof window

- Air cleaner double element

- Deck guard

- High efficiency fuel filter

- Hydraulic oil filter

- Komtrax

- Lockout, tagout

- Radiator dustproof net

- V-shaped fin radiator

- Cab guard - Full front guard OPG level 2 (ISO 10262)

- Cab guard - Bolt-on top guard OPG level 2 (ISO 10262)

- Cab guard - Half front guard

- Fire extinguisher

- Handrail (rear of the cab)

- In-line filter

- Revolving lamp for stoppage control identification

- Seat belt reminder revolving lamp

- Track frame full roller guard

- Track frame undercover